The mechanical and scientific phrase “fatigue life” describes how long a material or thing can resist intense loads before breaking down. The type of material utilised, as well as its structure, form, and temperature variations, can all have an impact on fatigue life. Read more about fatigue calculation and the formulas required.

Fatigue Life: What it is and Why it Matters

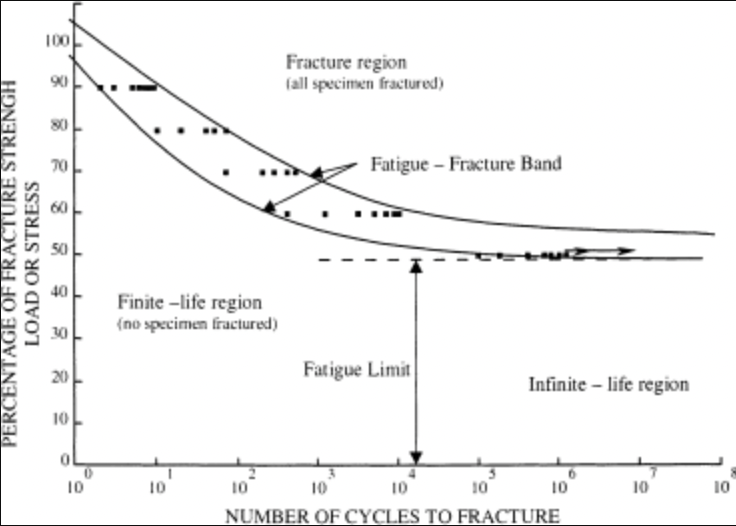

The number of stress cycles a piece of equipment or material can endure before failing is typically used to calculate its fatigue life. The nominal stress concentration value, often lower than ultimate tensile stress limits, is one of the stress values taken into account when determining fatigue life. A second figure, the yield stress limit, may be higher than the top tensile stress limit.

A material’s design can increase the stress on an object during use. For instance, rounder areas that spread the weight and pressure of a load across a broader surface area are often less stressed than sharper angles, such as the corners of a square object.

There may be minute fractures and pinpoint holes growing at the site of the most significant tension before weariness becomes obvious.

The fracture will eventually grow or lengthen to the point where it is not just obvious but also visible. Usually, the object completely fails not too long after one of these faults starts. At the first hint of any problem, specific materials and things are taken out of service.

Metal pieces that appear bent or bowed are an example of this damage, which may not be visible until the item splits in half. Rotor blades that were once constructed of pure metal may develop more minor fractures and fissures along their length due to various stress conditions, such as temperature fluctuations and wind shear. Altitude fluctuations must be examined because they can also increase stress, especially when they reach 50% of that material’s estimated everyday fatigue life. Helicopter rotor blades are currently made of various materials intended to absorb stress loads with better give and lengthen their fatigue life.

What Affects Fatigue Life?

Fatigue life is influenced by temperature, surface quality, metallurgical microstructure, oxidising or inert substances, residual stresses, scuffing contact (fretting), and others.

What is Fatigue Testing?

Fatigue testing is a specific form of mechanical testing that involves repeatedly loading a sample, a coupon, or a full structure. These tests are performed to find crucial spots, gather information on fatigue life and fracture propagation, or show the stability of a system that may be subject to fatigue.

What is Fatigue Threshold?

The critical threshold below that breaks in a material subject to cyclic loading can no longer propagate is called the “fatigue threshold.” To understand the underlying principles of the fatigue threshold, which is a crucial parameter in design and failure analysis, many studies have been done in recent years.

Conclusion

The amount of loading (stress or strain) cycles of a particular type that a specimen can withstand before failure of a specific kind is known as the fatigue life. There is a theoretical stress amplitude for some metals, such as steel and titanium, below which the material would not fail for an infinite number of cycles. The fatigue limit, endurance limit, or fatigue strength are all terms used to describe this value.